For integrators and manufacturers of engineering machinery armrest console systems, selecting the right electronic control joystick (Joystick Controller) is critical to project success. It is not only the core interface for the operator to interact with the machine, but its performance, reliability, and level of integration directly impact the quality and u ser experience of the entire electrical control system. This article systematically outlines the key considerations and steps for selecting industrial joysticks.

Step 1: Define System Requirements and Interfaces

Before making a selection, it is essential to have a clear understanding of your system requirements.

1.Mechanical and Electrical Interfaces:

- Mounting Method: Determine how the joystick controller will be mounted on the armrest console (top-mounted, side-mounted, panel-mounted) and the required mounting hole spacing and depth limitations.

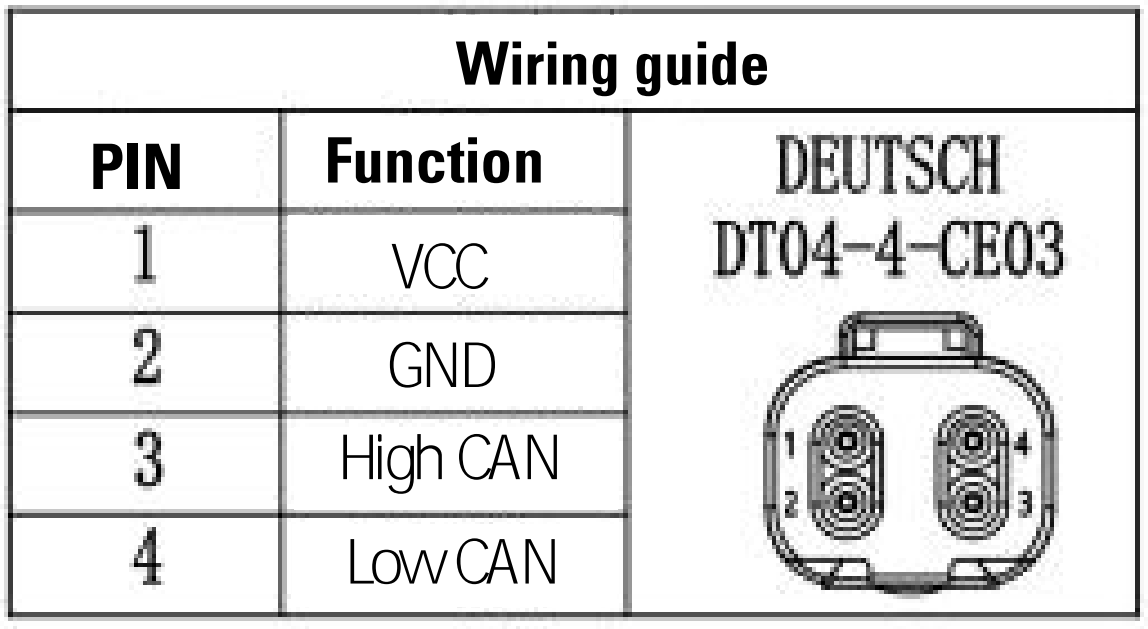

- Wiring Harness and Connectors: How much space is reserved for the industrial joystick‘s wiring harness? What type of connectors (e.g., AMP, Deutsch) are preferred from the supplier? This directly affects internal wiring and neatness within the armrest console.

2.Control Functional Requirements:

- Number of Axes and Functions: How many axes of electrical control are needed? (e.g., a single joystick controller for 2-axis travel control, dual industrial joysticks for 4-axis control of excavator boom, arm, etc.). Is there a need for integrated buttons, thumbwheels, potentiometers, or emergency stop switches?

- Ergonomics: The industrial joystick‘s shape, grip feel, operating torque, and return force must align with the target machine’s operational habits and ensure operator comfort during prolonged use.

Step 2: Evaluate Core Technology and Performance

This stage involves assessing the technical capabilities of the joystick controller itself, which directly determines the performance ceiling of the electrical control system.

1.Sensing Technology: This is the core of the industrial joystick.

- Hall Effect: The current mainstream and preferred technology. It uses non-contact magnetic sensing, has no physical wear, extremely long lifespan, excellent resistance to vibration, dust, and water, high precision, and no temperature drift. It is ideally suited for the harsh conditions of engineering machinery.

- Potentiometer: A contact-based technology subject to physical wear, limited lifespan, and sensitivity to dust and humidity. Its advantage is lower cost, but it is being gradually phased out for integration projects prioritizing high quality and reliability.

2.Output Signal Protocol: The “language” between the joystick controller and the vehicle’s main electrical control unit (ECU/PLC) must match.

- Analog: Voltage or current signals (e.g., 0-5V, 4-20mA). Simple interface, wide compatibility, a common choice.

- CAN Bus (CAN J1939/CANopen): Digitization is the future trend. Offers superior anti-interference capability; a single cable can transmit data for all axes and buttons, greatly simplifying wiring and enhancing system reliability and intelligence (e.g., enabling parameter configuration, fault diagnosis)

3.Ingress Protection (IP) Rating:

Engineering machinery environments are filled with dust, oil, and moisture. The selected industrial joystick should have a minimum rating of IP67 (dust-tight and protected against temporary immersion) to ensure internal components are not damaged during vehicle washing or rainy operation.

Step 3: Assess Supplier and Integration Support Capabilities

For integrators, the overall capability of the supplier is as important as the product itself.

- Excellent suppliers offer deep customization services for joystick controllers, including: customizing handle grip shape and color to match the cab style, customizing button functions and layout, customizing cable length and connector types, and even customizing output protocols and characteristic curves. This helps your armrest console system develop a unique market competitive edge.

2.Technical Support and Collaborative Development:

- Can the supplier provide detailed technical documentation, circuit schematics, and 3D models (STEP files) for the industrial joystick?

- Do they have the capability for collaborative development with application engineers to solve electrical control integration challenges?

3.Quality and Reliability Assurance:

- Inquire whether their production process for joystick controllers follows strict quality management systems (e.g., ISO 9001).

- Request relevant test reports, such as vibration, shock, temperature cycling, and EMC (Electromagnetic Compatibility) tests, to ensure their industrial joysticks meet national or international standards for engineering machinery.

4.Supply Chain Stability:

- Evaluate the supplier’s production capacity, delivery lead times, and inventory strategies for electrical control components to ensure they can meet your project timeline and mass production needs, avoiding delays in overall system delivery due to shortages of a single component.

Step 4: Total Cost of Ownership (TCO) Analysis

Do not focus solely on the unit price of the industrial joystick. Conduct a comprehensive Total Cost of Ownership (TCO) analysis.

- Direct Costs: Joystick controller purchase price.

- Integration Costs: Simpler installation, easier wiring (e.g., CAN Bus), and less debugging time can all reduce your overall electrical control integration costs.

- After-sales and Maintenance Costs: Choosing high-reliability industrial joysticks (e.g., Hall effect technology) significantly reduces failure rates, minimizes after-sales claims and maintenance costs, and protects your brand reputation.

Conclusion: Making an Informed Choice

Selecting an electronic control joystick for an engineering machinery armrest console system is a strategic decision. By following the steps above, you can make a scientific choice from the myriad of products available:

- Look Inward: Clearly define your own electrical control requirements.

- Look Outward: Focus on joystick controllers that use Hall effect technology, support CAN Bus, and have a high IP Rating (IP67+).

- Look Forward: Choose partners who offer excellent customization services for industrial joysticks, strong technical support, and a stable supply chain, rather than just being component suppliers.

By selecting a technologically advanced, reliable, and easy-to-integrate industrial joystick, you can not only enhance the value and competitiveness of the entire armrest console system but also provide end-users with a safer, more efficient, and comfortable operating experience through superior electrical control.

Contact Now: Cecilia Wu

Tel/WhatsApp: +86 18018519157

Email: wusiqi@halljoystick.com

Get detailed test videos and reports for truly reliable control solutions!