Industrial joysticks, as an important control device, are extensively used in various industrial automation fields such as mechanical manufacturing, aerospace, marine control, robotics, and more. Selecting an industrial Joystick that suits your specific needs not only increases work efficiency but also ensures precision and safety in operation. This article will provide a detailed guide on how to select the right industrial joystick for your requirements from multiple perspectives.

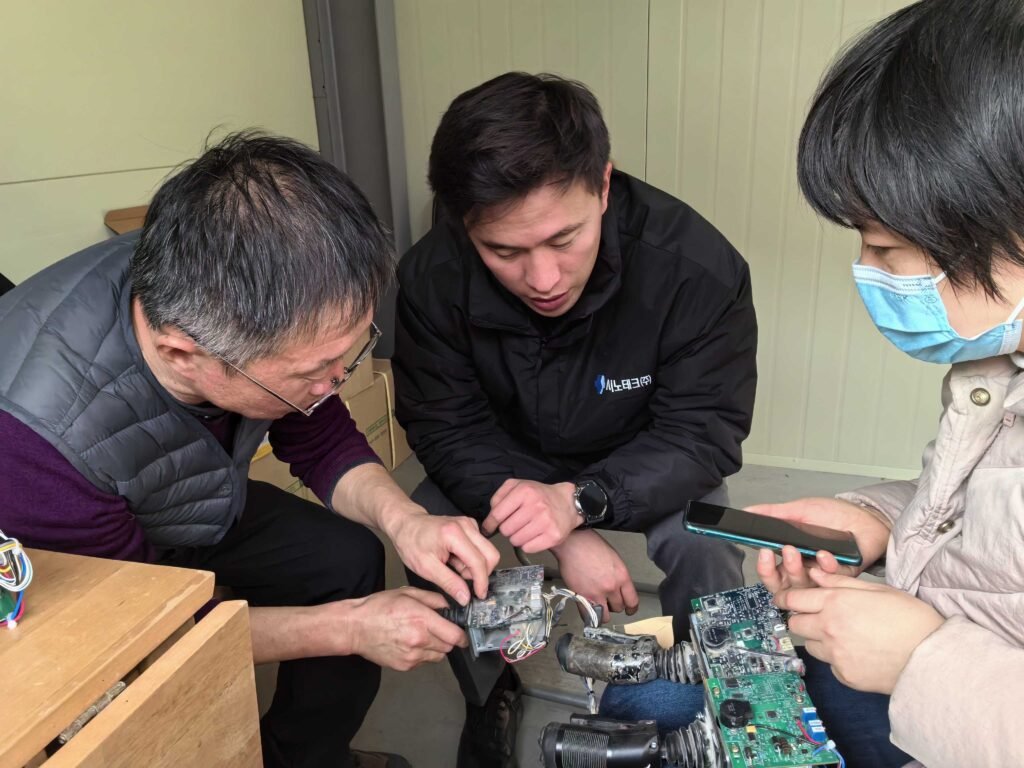

If your machines have an original joystick that was installed before, it would be very helpful if you could provide the part number of the joystick controller. Having the accurate part number will facilitate a smoother ordering process and help avoid any potential delays or complications that could arise from incorrect parts being ordered. Thank you in advance for your cooperation and assistance in this matter.

Technical parameters of an industrial joystick are an important basis for selection. Here are some of the key technical parameters

Size

Technical parameters of an industrial joystick are an important basis for selection. Here are some of the key technical parameters:The size of the joystick directly affects its applicability and comfort in operation. Different application scenarios require joysticks of various sizes, and selecting the appropriate size can enhance the convenience and precision of operation.

Model of Operation

There are various modes of operation for joysticks, including single-axis, dual-axis, multi-axis, etc. Different operation modes are suited for different control requirements, and selecting the right one can improve control flexibility and efficiency.

Output Signal

Joysticks have various output signal types, such as analog signals, digital signals, pulse signals, etc. Different signal types are suitable for various control systems, and choosing the right signal ensures compatibility and stability between the joystick and control systems.

Wiring Method

Wiring methods for joysticks include bottom exit wiring, side exit wiring, etc. Different wiring methods are suited for different installation environments, and choosing the appropriate method can improve installation flexibility and aesthetics.By considering these key technical parameters comprehensively, you can select the industrial joystick that best suits your needs, enhancing work efficiency and ensuring precision and safety in operation.

Ergonomic design is another important factor to consider when choosing an industrial joystick. A good ergonomic design can improve comfort and efficiency in operation and reduce fatigue. Here are some considerations for ergonomic design:

Comfort of Grip

The grip part of the joystick should conform to ergonomic design, being comfortable to hold and not prone to slipping.

Operation Force

There are various modes of operation for joysticks, including single-axis, dual-axis, multi-axis, etc. Different operation modes are suited for different control requirements, and selecting the right one can improve control flexibility and efficiency.

Output Signal

The operating force of the joystick should be moderate, neither too heavy nor too light. An overly heavy operating force can increase operator fatigue, while too light of a force can decrease precision.

Button Layout

The layout of buttons on the joystick should be reasonable and user-friendly. The size and position of the buttons should follow ergonomic principles to prevent accidental operation.

Selecting an industrial joystick that fits your requirements requires considering multiple factors, including application scenarios, technical parameters, ergonomic design, brand and supplier, cost-effectiveness, user reviews, and actual testing. Through comprehensive analysis and comparison, you can select the industrial joystick that best suits your needs, improving work efficiency and ensuring precision and safety in operation.

5F Building E, 1355 ChengBei Road, Jiading, Shanghai, China 201807