At Shanghai Chengong Electrical Control Technology Co,Ltd.,we combine innovation, precision, and reliability to deliver world-class electrical control joysticks for aerial work platforms, construction machinery, and agricultural equipment. Our HJ40 series control joysticks are engineered to outperform industry standards, offering a superior replacement for the Penny Giles JC4000 Series and other leading models. Backed by data-driven performance metrics, the HJ40 Series is the ultimate choice for operators who demand excellence.

HJ40 Series: Precision Engineered, Data-Backed Performance

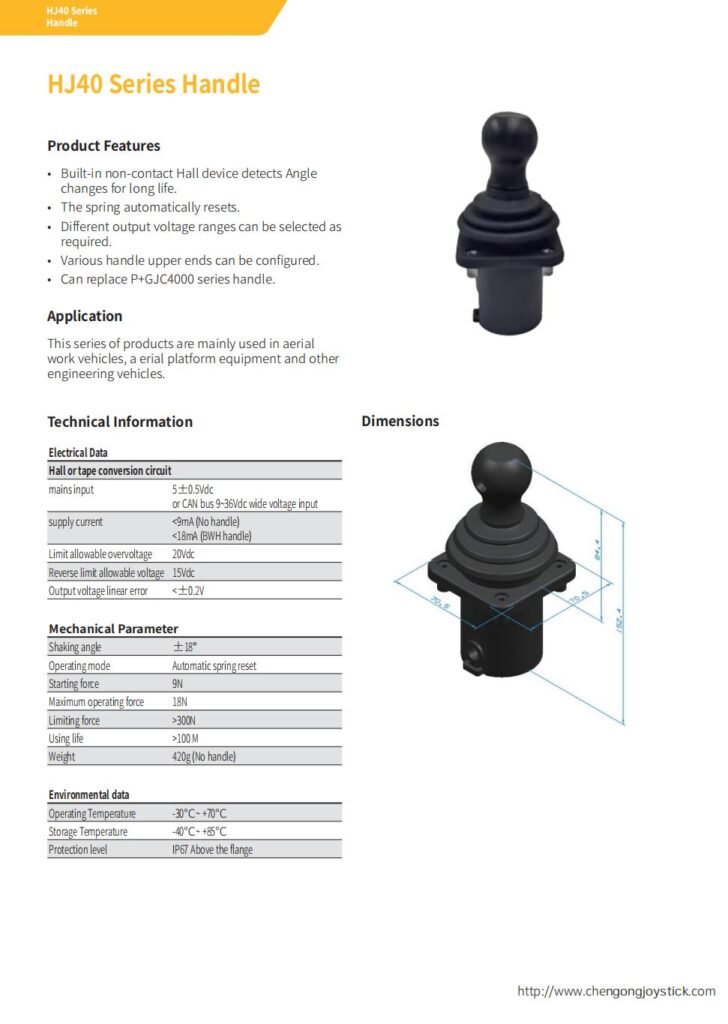

The HJ40 Series is designed to meet the rigorous demands of modern machinery. Here’s how it stands out with measurable results:

1. Unmatched Durability

- Operating Life: Tested to withstand over 1 million cycles without performance degradation.

- Environmental Resistance: Rated for operation in temperatures ranging from -40°C to 85°C, ensuring reliability in extreme conditions.

- IP Rating: Features an IP67 rating, making it dustproof and waterproof for harsh job sites.

2. Enhanced Signal Stability

- Signal Accuracy: Delivers <0.5% signal deviation for precise control, even in high-vibration environments.

- Response Time: Achieves a rapid <10ms response time, ensuring real-time control for critical operations.

- EMI Resistance: Designed to minimize electromagnetic interference, maintaining signal integrity in electrically noisy environments.

3. Seamless Compatibility

- Global Fit: Compatible with equipment from leading brands like Genie, JLG, Skyjack, Haulotte, XCMG, Zoomlion, and Lingong.

- Plug-and-Play Design: Reduces installation time by 30%, ensuring minimal downtime during upgrades.

- JC4000 Replacement: Directly replaces the Penny Giles JC4000 Series, offering improved performance and cost efficiency.

4. Proven Global Performance

- Market Reach: Sold in 50+ countries across North America, Europe, Asia, and beyond.

- Customer Satisfaction: Boasts a 98% customer satisfaction rate based on post-purchase feedback.

- Field-Tested Reliability: Over 10,000 units deployed globally, with a <0.1% failure rate in the first year of operation.

Applications Across Industries

The HJ40 Series is trusted by operators in diverse industries, delivering measurable improvements in performance and efficiency:

1. Aerial Work Platforms

2. Construction Machinery

Delivers smoother operation for excavators and loaders.Ensures precise of the cranes load positioning, minimizing errors.

3. Agricultural Equipment

Why Choose Shanghai Chengong Technology?

With a commitment to innovation and quality, Shanghai Chengong Technology is your trusted partner for industrial joystick solutions. Here’s why customers worldwide choose us:

- Patented Technology: Over 15 patents in handle design and signal transmission.

- Global Expertise: 10+ years of experience serving international markets.

- Comprehensive Support: 24/7 technical assistance and a 2-year warranty on all products.

Upgrade to the HJ40 Series Today

If you’re looking for a reliable replacement for the Penny Giles JC4000 Series or any other industrial joystick, the HJ40 Series is your answer. With its data-backed performance, global compatibility, and proven reliability, it’s the ultimate choice for enhancing your machinery’s efficiency and precision.

Contact us today to learn more about the HJ40 Series and discover how we can help you achieve superior performance in every operation.